CNG Cylinder Testing Process at Green Energy Solutions Pune

Ensuring the safety and reliability of CNG cylinders is paramount, and at Green Energy Solutions Pune, we take this responsibility seriously. As India's Leading CNG Cylinder Testing Company, we adhere to a rigorous testing process that ensures your CNG cylinders meet the highest safety standards and comply with regulatory requirements.

Here's a comprehensive look at our CNG Cylinder Testing Process:

Ensuring the safety and reliability of CNG cylinders is paramount, and at Green Energy Solutions Pune, we take this responsibility seriously. As India’s Leading CNG Cylinder Testing Company, we adhere to a rigorous testing process that ensures your CNG cylinders meet the highest safety standards and comply with regulatory requirements.

De-pressuring & Degassing of Cylinders

The process begins with the safe de-pressuring and degassing of the CNG cylinders, ensuring that they are ready for thorough inspection and testing.

Valve Opening and External Inspection

Our expert technicians carefully open the valves and perform an external inspection of the cylinders, checking for any visible signs of damage or wear.

External Inspection (thickness, bulge, burn, dents, dig)

We meticulously examine the exterior of the cylinders, assessing factors such as thickness, bulges, burns, dents, and dings to identify any anomalies that may affect safety.

Internal Cleaning of Cylinders

To ensure the integrity of the cylinders, we conduct a thorough internal cleaning process, removing any contaminants or residues that could compromise safety.

Checking of Tare Weight

The tare weight of the cylinders is checked to ensure accurate measurements and adherence to regulatory standards.

Internal Inspection

Our experts perform an internal inspection to identify any internal defects or issues that may affect the cylinder's performance.

Hydrostatic Stretch Testing - Water Jacket and Direct Expansion Method

We employ advanced hydrostatic stretch testing techniques, utilizing both the water jacket and direct expansion methods to assess the structural integrity of the cylinders.

Cylinder Wall Thickness Measurement by Ultrasonic Thickness Tester

We use state-of-the-art ultrasonic thickness testers to measure the cylinder wall thickness with precision, ensuring compliance with safety standards.

Ultrasonic Flaw Detection Test

Advanced ultrasonic flaw detection tests are conducted to identify even the smallest imperfections within the cylinder walls, guaranteeing their safety.

Cylinder Drying, External Cleaning, and Painting

After testing, cylinders are meticulously dried, cleaned externally, and painted to protect against corrosion and maintain their appearance.

Fixing of Valves

The valves are securely fixed back onto the cylinders, ensuring proper functionality.

Assemble & Disassemble of CNG Cascades

For CNG cascades, we skillfully assemble and disassemble them as required, guaranteeing their safety and reliability.

Test Mark Sign

A test mark sign is affixed to the cylinder, indicating that it has passed our rigorous testing process and is fit for use.

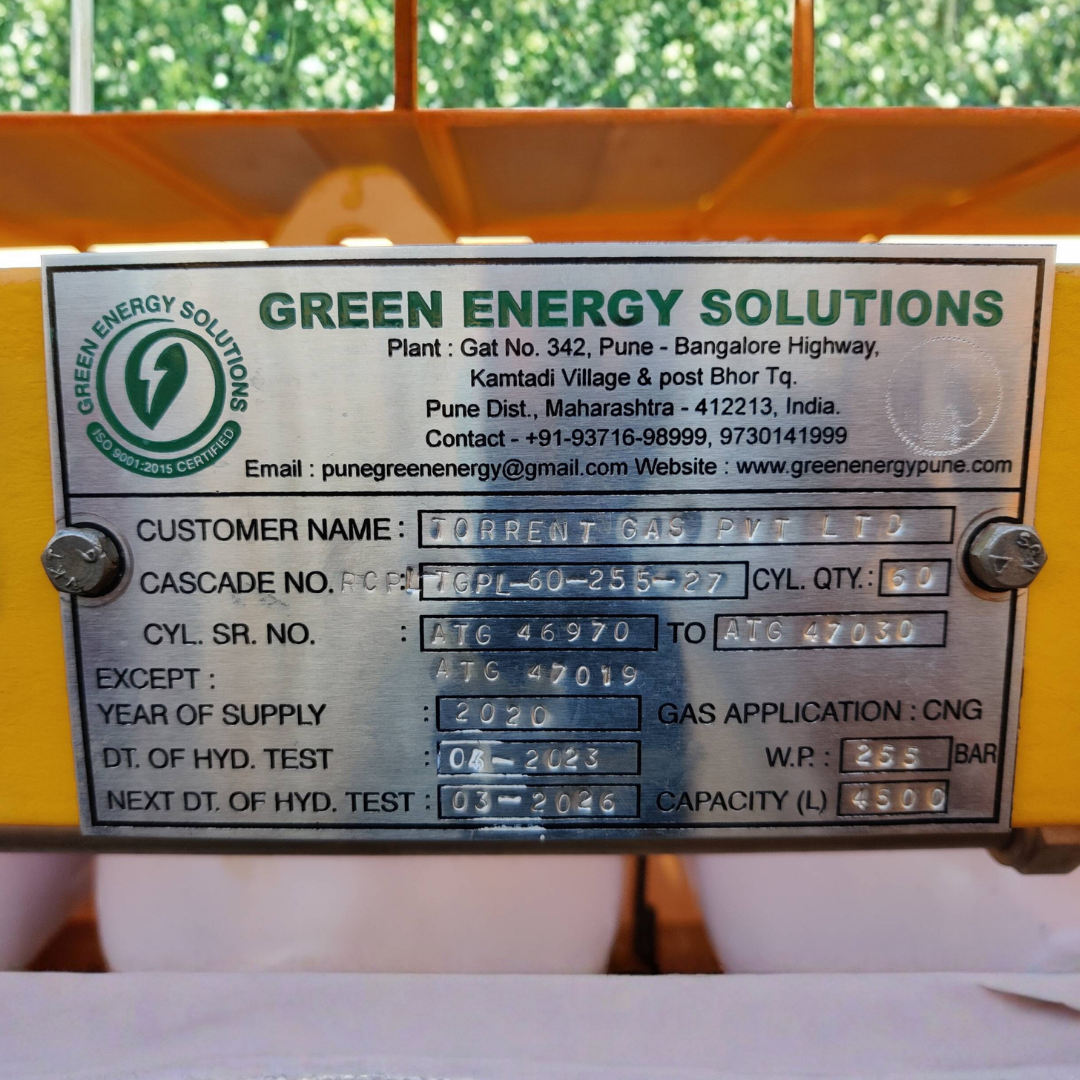

Delivery with Certificate and Metal Plate

Finally, we deliver the certified cylinders to you, complete with a certificate and metal plate, providing assurance of their safety and compliance.

At Green Energy Solutions Pune, we leave no stone unturned in ensuring that your CNG cylinders are safe, reliable, and in full compliance with regulatory standards. Trust us for a meticulous CNG Cylinder Testing Process that prioritizes your safety and the environment.

FAQ

What is the first step in the CNG cylinder testing process at Green Energy Solutions Pune?

The process begins with the safe de-pressuring and degassing of the CNG cylinders, ensuring that they are ready for thorough inspection and testing.

How can I identify a certified cylinder from Green Energy Solutions Pune?

A test mark sign is affixed to the cylinder, indicating that it has passed our rigorous testing process and is fit for use.

How are the certified cylinders delivered?

we deliver the certified cylinders to you, complete with a certificate and metal plate, providing assurance of their safety and compliance.