CNG Cylinder Testing in Pune

CNG Cylinder Hydro-Testing is a mandatory safety process to ensure that CNG (Compressed Natural Gas) cylinders remain fit for use and comply with PESO (Petroleum & Explosives Safety Organization) regulations. Here’s a clear breakdown for you:

1) What is Hydro-Testing?

Hydro-testing is a pressure test where the CNG cylinder is filled with water and pressurized to check for:

1) Leakage

2. Structural integrity

3) Expansion under pressure

a) Frequency

As per PESO guidelines, CNG cylinders must be hydro-tested every 3 years.

Cylinders past their expiry or with physical damage must be tested immediately.

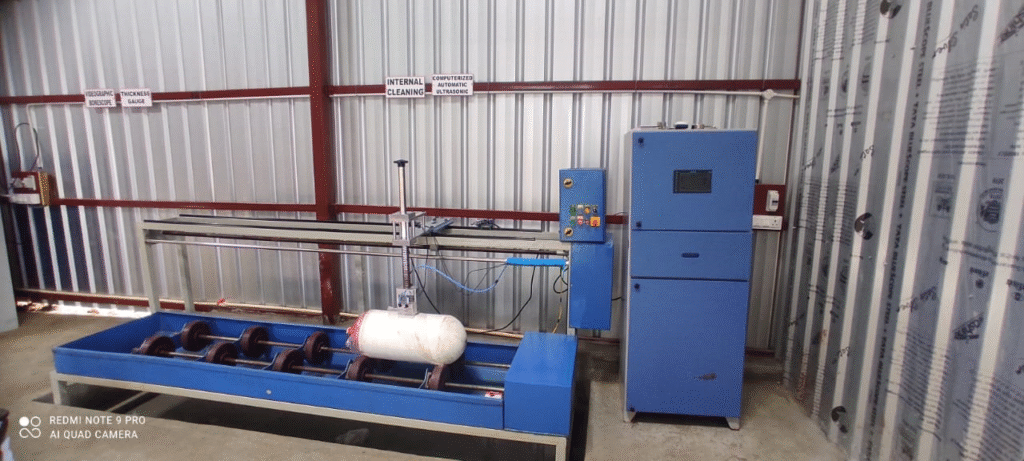

b) Hydro-Testing Process

- Pre-Inspection – Check external condition, dents, corrosion, or damage.

- Valve Removal – The CNG cylinder valve is removed safely.

- Filling with Water – Cylinder is filled with water to avoid risks associated with compressed gases.

- Pressure Test – Pressurized (usually at 330 bar or as per ISI standards).

- Measurement – Permanent expansion and deformation are checked.

- Drying & Painting – Cylinder is dried and repainted for protection.

- Valve Refitting & Leak Test – Reassembled and checked for leaks.

- Certification & Stamping – PESO-approved test certificate issued, and a new test due date is punched on the cylinder.

c) Documents Provided

Hydro-test certificate (valid for 3 years)

PESO approval marking

Test sticker on the cylinder

d) Importance

Legal requirement under Gas Cylinder Rules, 2016 (PESO India)

Ensures passenger & vehicle safety

Avoids penalties/fines during RTO or road checks

1) Type 1 Cylinders – All Metal

Type 1 cylinders are the earliest and most traditional form of CNG storage vessels, manufactured entirely from metal without any composite reinforcement. These cylinders are produced either from seamless steel tubes through hot spinning and forging or from aluminium billets, depending on the required application. Seamless steel cylinders have been in commercial use since the 1940s and remain the most widely adopted option due to their strength, durability, and proven safety record.

A major milestone in the evolution of CNG storage came in the late 1970s, when Italian manufacturers introduced high-strength, lightweight seamless steel cylinders. These provided a better balance betweenweight reduction and pressure endurance, which helped accelerate the growth of the CNG industry worldwide.

Certain international standards also permit the use of welded steel cylinders for CNG storage. However, such cylinders are subject to higher safety factors and more stringent testing requirements compared to seamless designs, due to the potential stress concentration at welded joints.

In addition to steel, aluminium Type 1 cylinders have also been developed. While more expensive, they offer a significant reduction in weight and are corrosion-resistant, making them attractive for specific automotive and industrial applications where weight is critical.

Overall, Type 1 cylinders continue to be the most cost-effective and durable option for CNG storage, though their relatively higher weight compared to composite designs (Type 2, 3, and 4) can limit their use in modern lightweight vehicle platforms.

2) Type 3 CNG Cylinders – Fully Wrapped Composite with Metal Liners.

Type 3 CNG cylinders have a seamless metal liner over wound on all surfaces by a composite reinforcement that provides between 75 and 90% of the strength to the vessel. The liner provides the rest of the strength, plus acts as a rigid membrane to hold the gas and provide extra impact resistance to the product.

There are over 2 million fully wrapped composite cylinders in use in portable applications such as breathing apparatus; medical oxygen storage and aircraft slide inflation.

Type 3 cylinders are used in a wide range of applications where weight reduction is important, for example in transit buses and delivery trucks. Type 3 cylinders have also been used on various OEM vehicles such as the Volvo and Volkswagen CNG cars. Suppliers of Type 3 containers include Luxfer, Dynetek, and Structural Composites, Inc.

3) Type 4 CNG Cylinders – Fully Wrapped Composite with Non-Metallic Liners.

Type 4 fuel containers have a plastic liner and a full overwrap of carbon fibre or mixed fibre construction. The liners of Type 4 tanks provide no structural strength to the product and act only as a permeation barrier. Although these liners are not gas tight, the rate of permeation has been found acceptable for use with CNG.

As a rule Type 4 CNG cylinders are fitted with impact protection on the domes, as the plastic liner does not provide a rigid backing to the composite overwrap.

Again, Type 4 cylinders are used where weight is important such as on buses, trucks and OEM vehicles such as the Volvo. Suppliers of Type 4 containers include Quantum, Ullit, Lincoln Composites, and Ragasco.